For over 40 years, at our site in Burnhaupt-le-Haut, Alsace, near the city of Mulhouse, we have been designing and producing flexible PCBs. Thanks to those many years of experience, Flex Connect has unique FPCB expertise.

A new chapter in the site’s history began in 2008 when the entity Flex Connect was created. At that time, the new management team set a goal: developing and promoting flexible PCBs in Europe, as well as building a lasting relationship based on trust with our customers and partners.

Every day, around 30 employees work to serve over 200 customers in France and around the world, with one third of our revenues coming from outside of France. We have recognised expertise in cutting-edge sectors such as aeronautics, aerospace, medical, electronics, defence, and more.

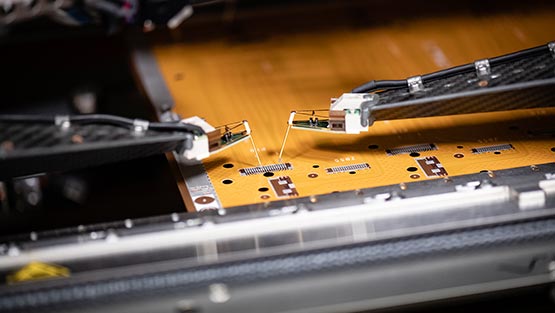

Our plant, which is entirely dedicated to the production of flexible PCBs, allows us to manufacture and deliver parts in individual units, in panels, or in rolls in order to meet any needs you may have. We offer all types of PCBs you can think of: single or double sided, multilayer, differential copper, jumpers, and more.

As a human-scale company, Flex Connect works hard every day to build lasting relationships with our customers based on trust and personalised service. Thanks to our partnership with Sofimeca, we have the industrial and financial support of this company with over 400 employees and annual revenues of over €60 million.